One-touch setup systems increases your profits

Leave a requestThanks to their modular design, our machines can apply labels to any types of bottles, jars, canisters, and flacons and vials with no wrinkling, shifting, or air pockets.

Continuous two-side labelling of product containers. Applying labels with no air pockets or wrinkling, labels are positioned to fit the surface recess.

Up to 14000 bottles per hour1–4 labelsHeight up to 300 mmContinuous two-side labelling of oval-sectioned, triangular-sectioned and other curved product containers. Applying labels to fit pre-defined positions.

Up to 12000 bottles per hour1–3 labelsWrap-around labelling of cylindrical (and even oval-sectioned) product containers. Clear labels remain clear, while embossed labels remain embossed.

Up to 12000 bottles per hour1–2 labelsWrap-around labelling of cone-shaped product containers, applying labels onto the lid positioned against side labels, aligning labels in the centre of the lid. The machine can lift the hobbock bail if needed.

Up to 2200 bottles per hour1–2 labelsPharmceuticals, cosmetics, liquids for e-cigarettes, stationery, paint – wraparound labels for small, lightweight, and unsteady product containers.

Up to 11000 bottles per hour1–2 labelsPositioning and gripping glass or plastic bottles by the top and by the bottom. Applying a front label, a back label, an excise label, a neck label, and a round label to pre-defined positions.

Up to 14000 bottles per hour1–5 labelsOnitex provides solutions for various filling options.

Jams with fruit slices, sauces, cosmetic creams, detergents that come in plastic or glass bottles and canisters – rest assured that the product volume will be identical across all containers.

Up to 3000 bottles per hour0.1–5 lFoaming liquidsCosmetics, paint, acids and alkalis, sanitizers, and other pharmceuticals. The discreet filling system makes it possible to quickly switch between products without spending too much time to clean the system.

Up to 1500 bottles per hour0.01–1 lUp to 90°CFoaming liquidsCorrosive liquidsOnitex provides solutions for various capping types.

Plastic and aluminium ROPP bottle caps. Threading on both pieces is aligned to ensure that caps are fully screwed in.

Up to 3000 bottles per hourAuto feedBoth trigger caps and dosers are screwed in with the required torque.

Up to 3000 bottles per hourPull rings are pressed in, caps screwed in tight.

Up to 3000 bottles per hourBathroom detergents and other similar products.

Up to 3000 bottles per hourThe capper is suitable for various types of such caps, readjustment takes roughly 10 minutes.

Up to 1200 bottles per hourUp to 3000 bottles per hourAuto feedThe capping machine is suitable for large diameter lids up to 25 cm.

Up to 1200 bottles per hourPipette caps fit the neck of the vial precisely, they are then properly aligned and screwed in with pre-set torque.

Up to 3000 bottles per hourAuto feedVarious machine types for different objectives and production capacities.

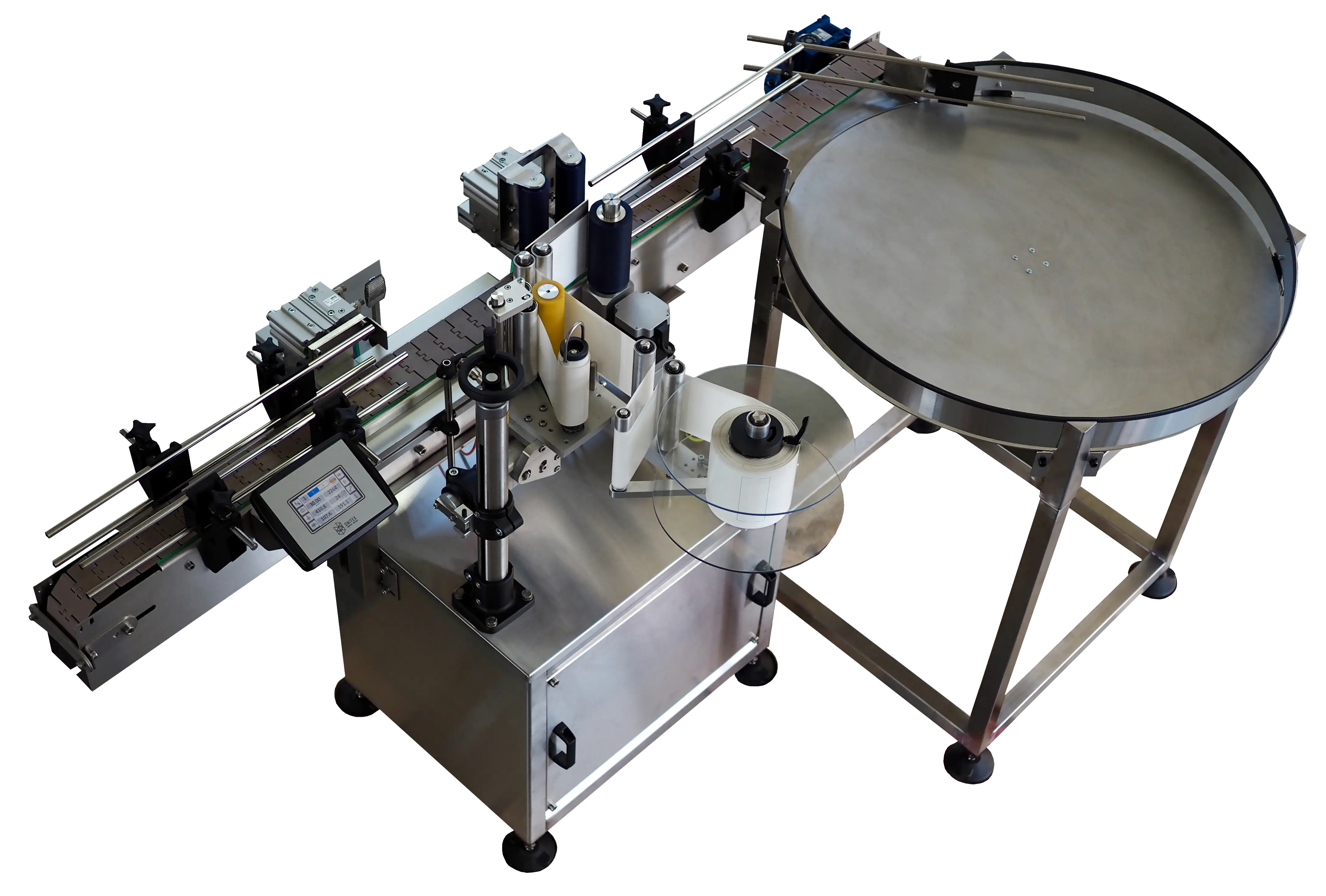

A compact machine that applies one or two wrap-around labels onto cylindrical or cone-shaped product containers.

The machine applies one or two wraparound labels onto cylindrical or cone-shaped product containers, and one lid label.

Various machine types for different objectives and production capacities.

Volumetric filling with three batcher options: cylinder system, liquid meters, or peristaltic pumps. 4 to 10 nozzles. Manage the nozzle height thanks to the sychronous drive using the algorithm for liquids prone to foaming.

A mini-line: volumetric filling based on 1 to 3 peristaltic pumps with a bottom-up filling system, complete with a universal roller capper with an automated cap feeder and a labeller which can apply 1 to 2 wrap-around labels – all in one compact machine. It comes with a template system for quick readjustment.

Various machine types for different objectives and production capacities.

We'll help you find the right products and pricing for your business. Fill the form below or give us a call +386 64 152 151. You can also send your request to [email protected].