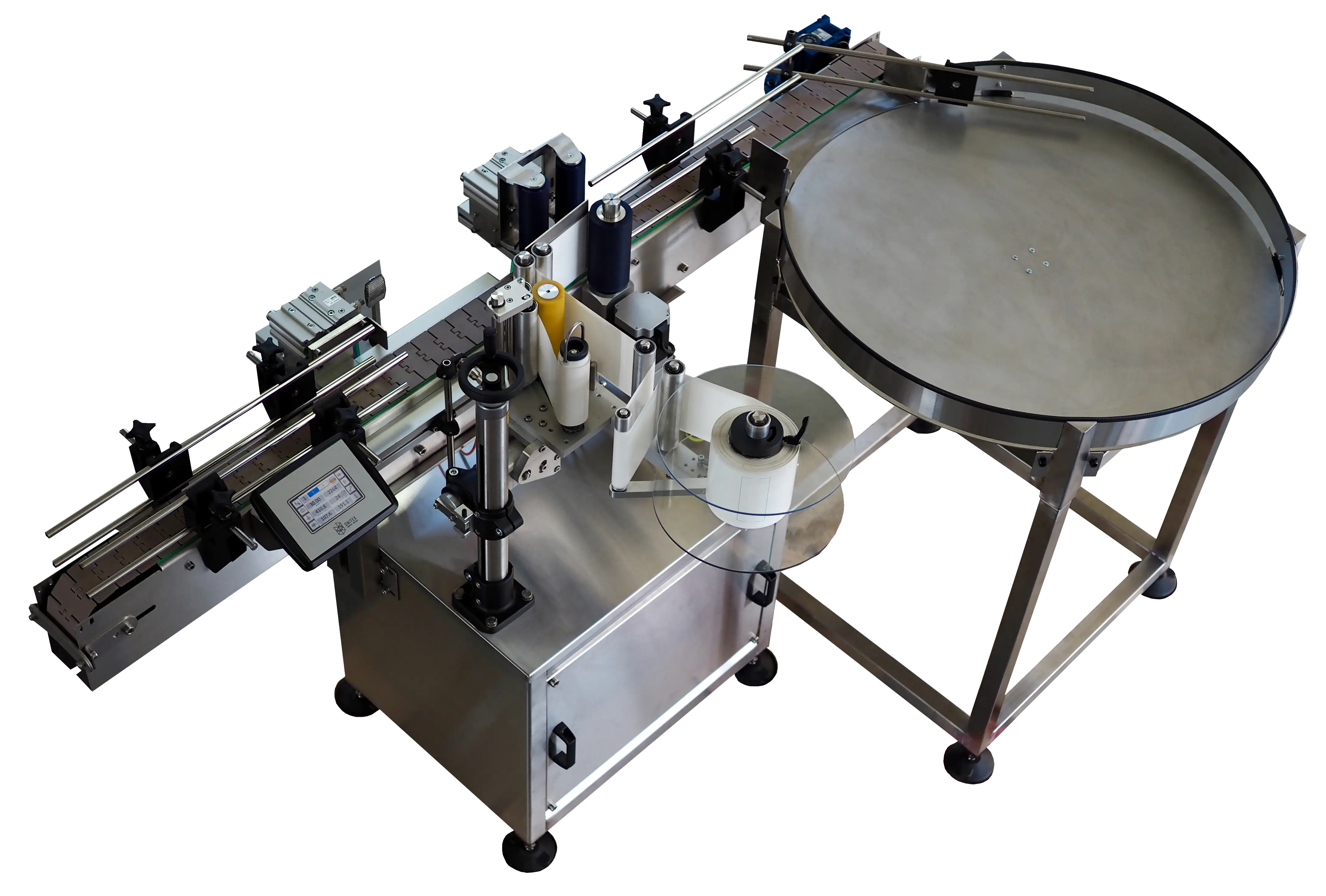

Exterior

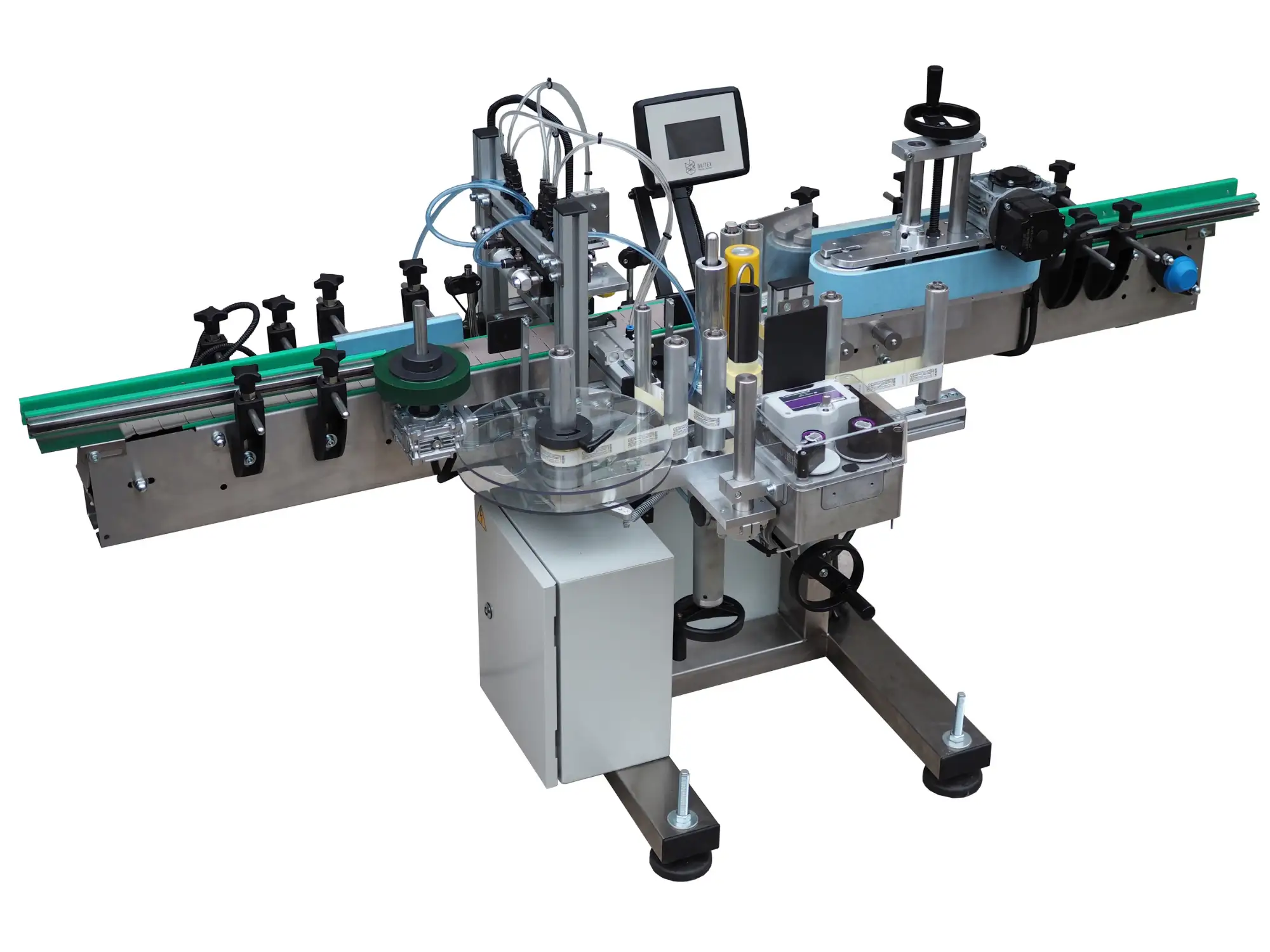

The machine design makes it possible to install various modules depending on the objective:

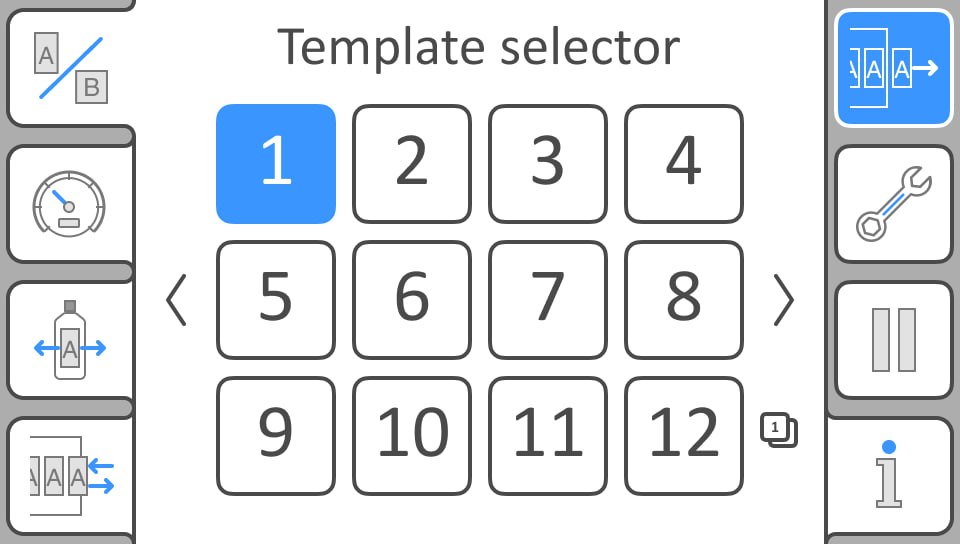

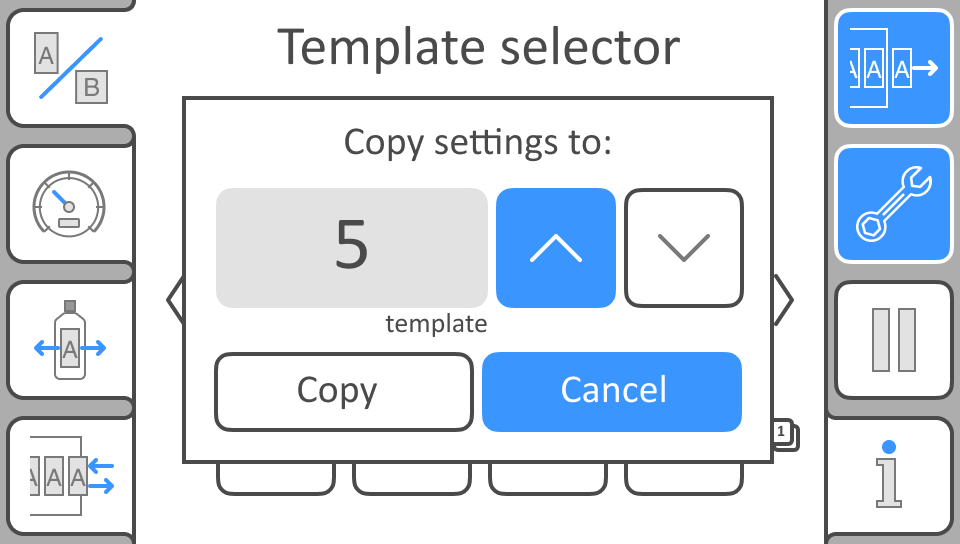

Touch screen

The screen allows you to manage and to set up all machine modules, and to switch between different templates for various product container types. There are two synchronized control panels to ensure more convenience for the operator.

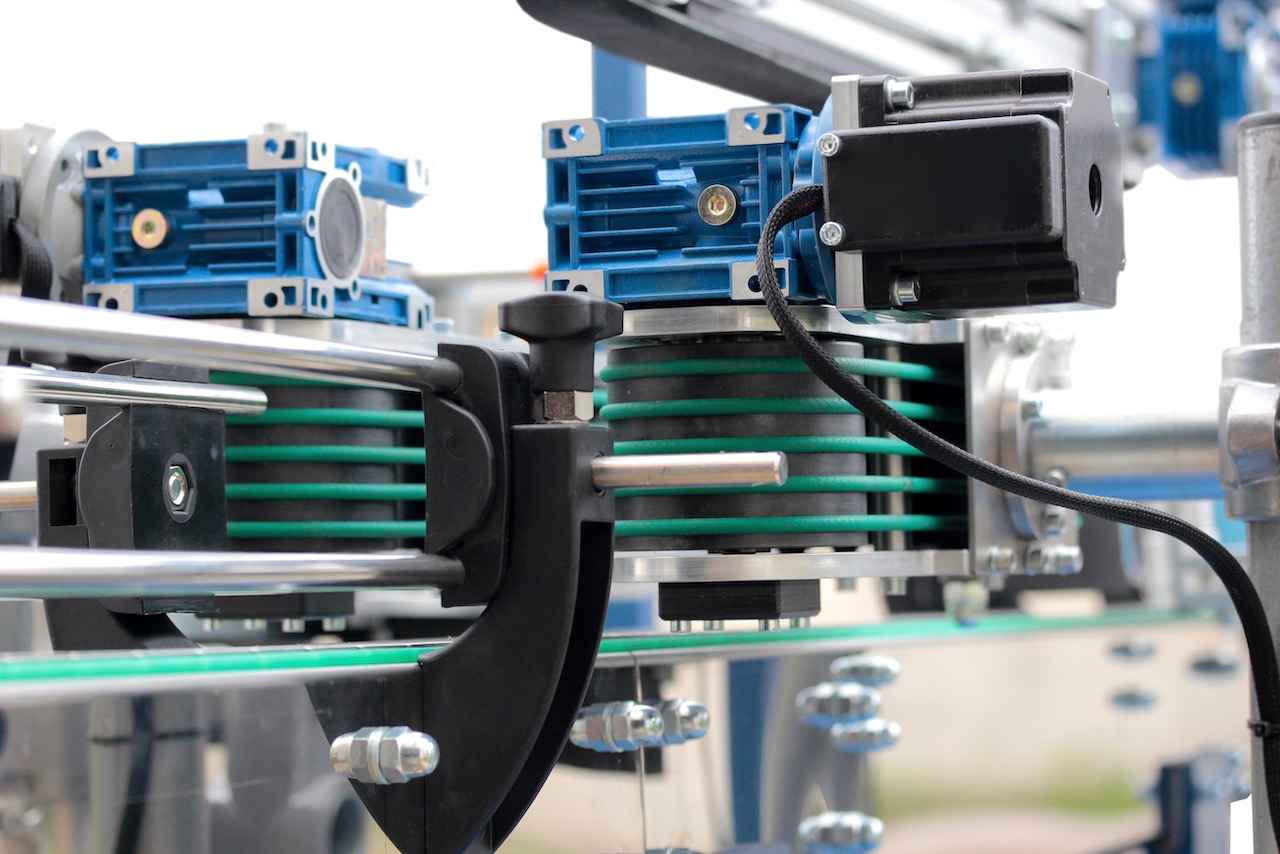

Conveyor belt step drive

The step drive ensures consistent speed: the load does not impact the conveyor belt speed.

Roller labelling unit

The roller unit holds and rotates cylindrical or cone-shaped containers in order to properly apply wrap-around labels. The unit evens out the container to ensure that label edges are properly aligned. It is synchronized with the applicator thanks to the step drive.

А150 applicator

The applicator dispenses labels at the exact moment, with the exact speed, and the exact tape tension. Label height is up to 300 mm depending on the applicator model.

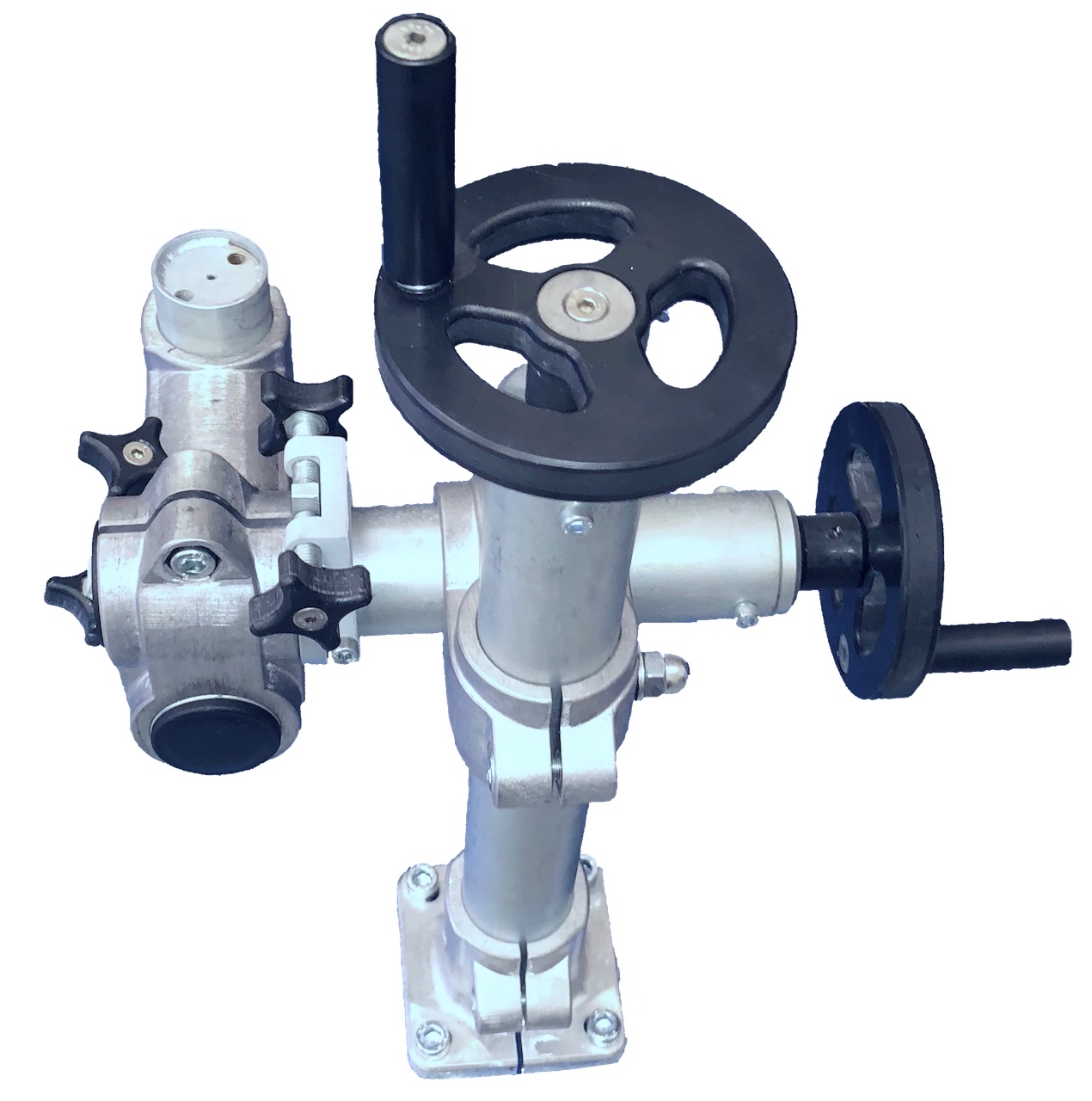

Applicator Stand

The applicator is adjustable and lockable, with five mobility degrees.

Stainless steel frame

The frame ensures the overall sturdiness of the structure making it possible to easily install all modules necessary to deliver the desired result.

Container divider

The divider provides the necessary minimal intervals between containers on the conveyor belt. Synchronized with the other modules thanks to the step drive.

Stainless steel receiving table

The applicator dispenses labels at the exact moment, with the exact speed, and the exact tape tension. Label height is up to 300 mm depending on the applicator model.

.jpeg?h=846599732b3e3f64d0bbbc0881e7b4b9)

.jpeg?h=16c2a99a431f9eb48b82f283dea627a6)

.jpeg?h=16c2a99a431f9eb48b82f283dea627a6)

.jpeg?h=b61f57bed41b1c8b666d130364f5cd26)