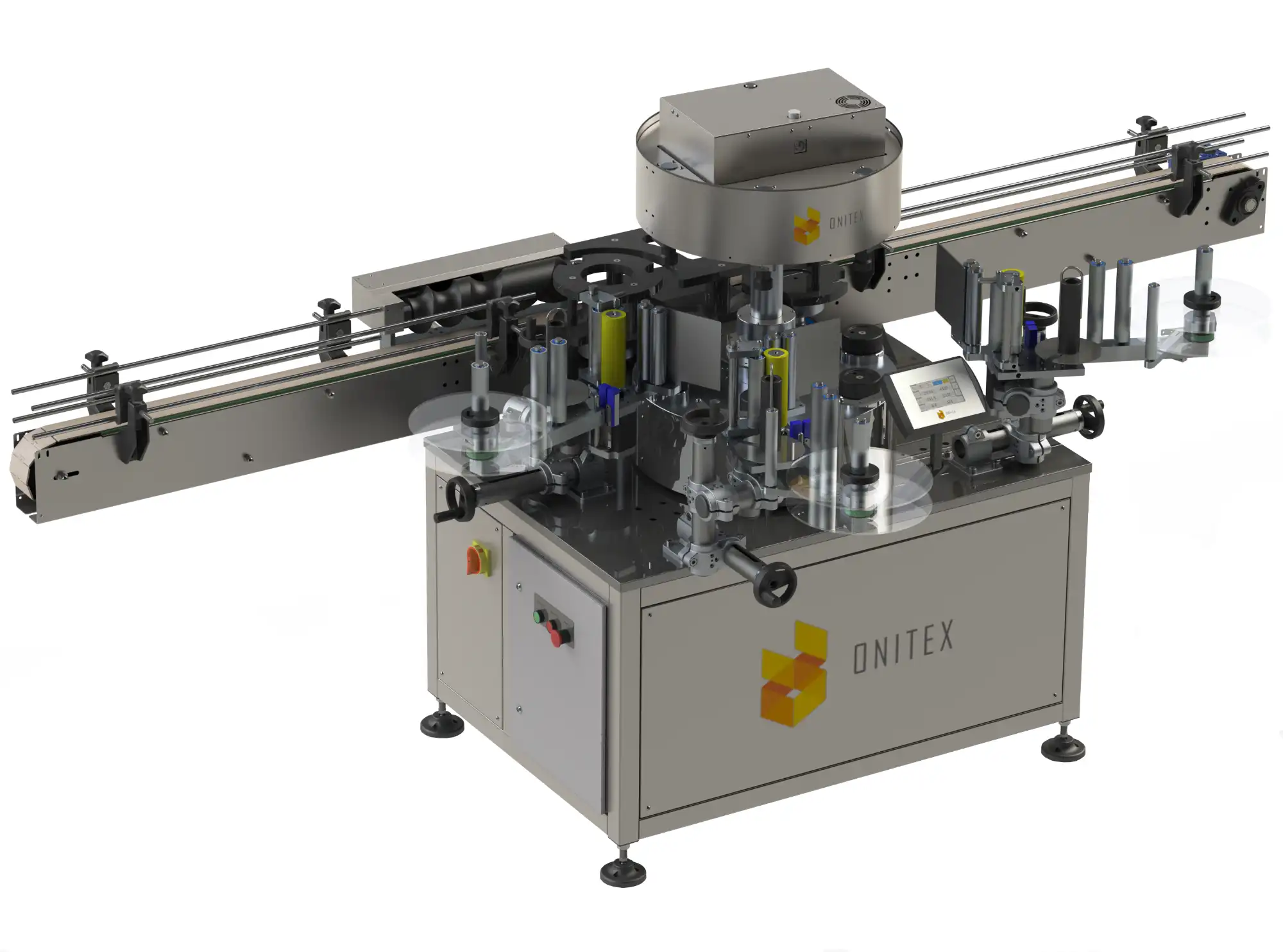

Appearance

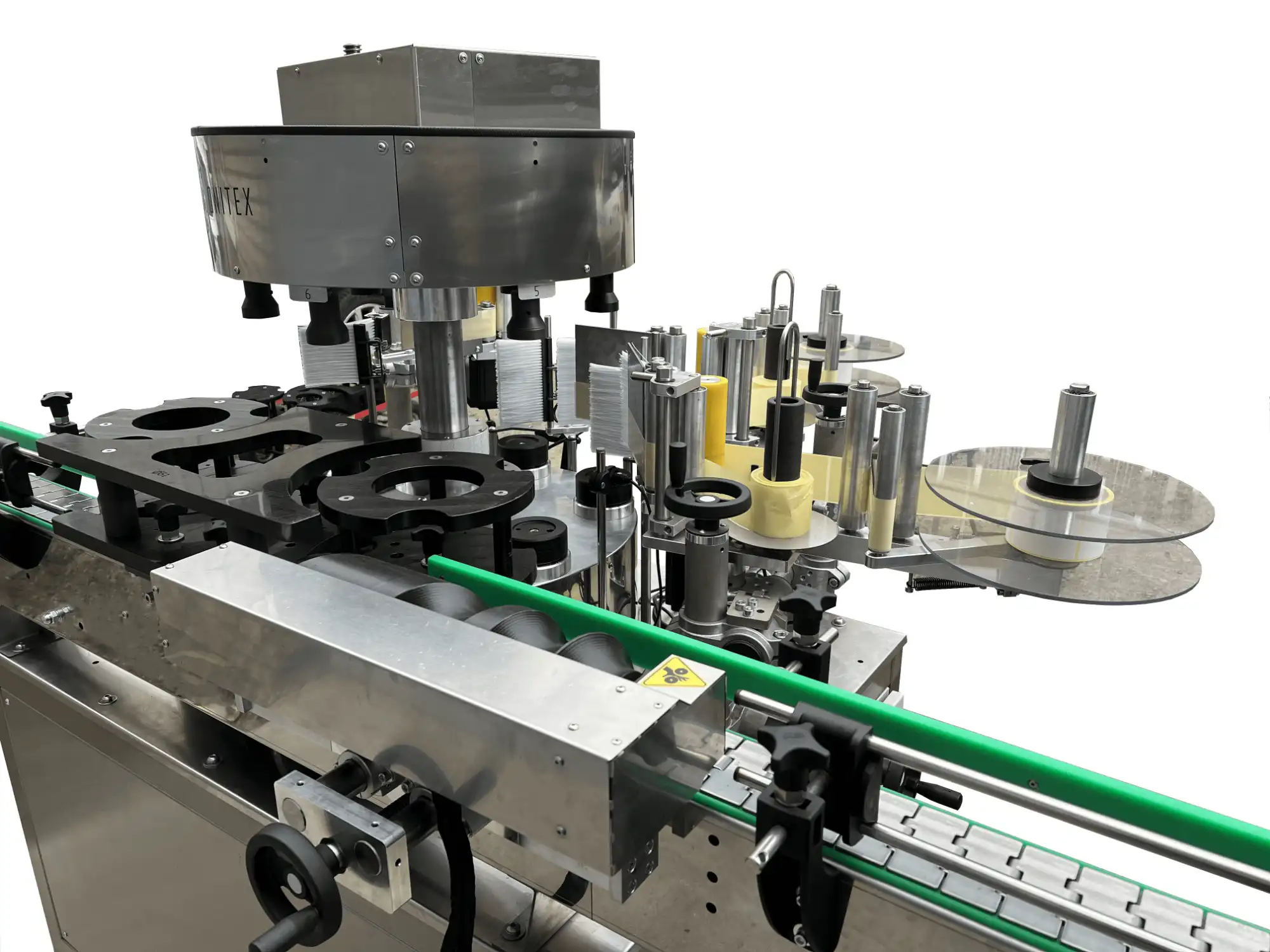

The design of the machine allows the installation of various modules depending on the task:

Turret

The turret is made according to the shape of the container, it is responsible for supplying the container to the table and for removing the container from the table (at the end).

Bells

Bells are made according to the shape of the container, they are responsible for pressing and fixing the container on the tables.

Touch screen

The control panel is ready for operation in half a second after the machine is powered on. Any setting is available in two or three finger touches, the responsiveness of the interface is at the iPhone level. The hint system will help in case of an incorrect combination of parameters and will inform you about an emergency situation on the line. The technology used ensures that the firmware of the machine will never fall down.

Infeed Screw

The Infeed Screw is made according to the shape of the container, it is responsible for separating the container flow and feeding the container into the turret.

Applicator

Issues the label at the right moment, with the right speed and tension of the tape. The label height is up to 300mm, depending on the applicator model.

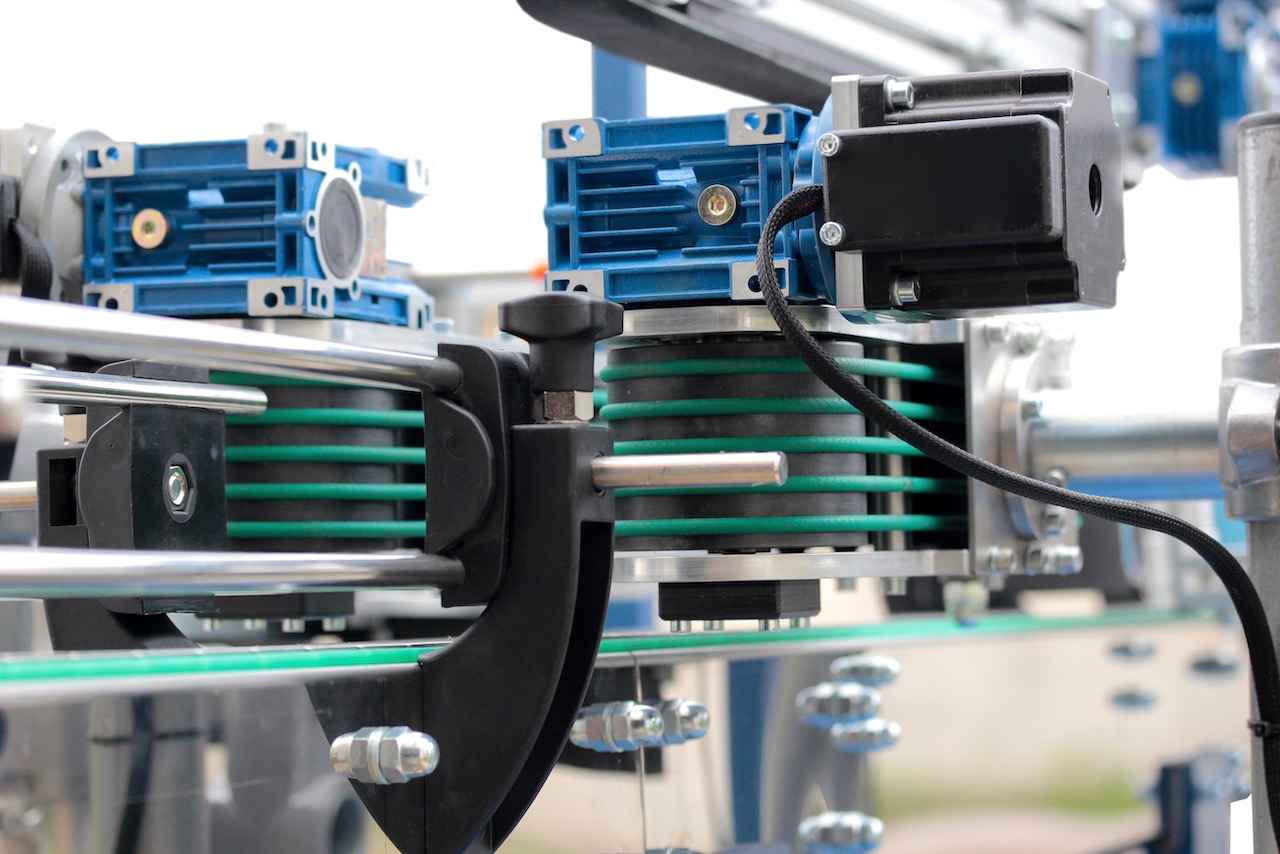

Conveyor

Chain conveyor for the supply and removal of containers.

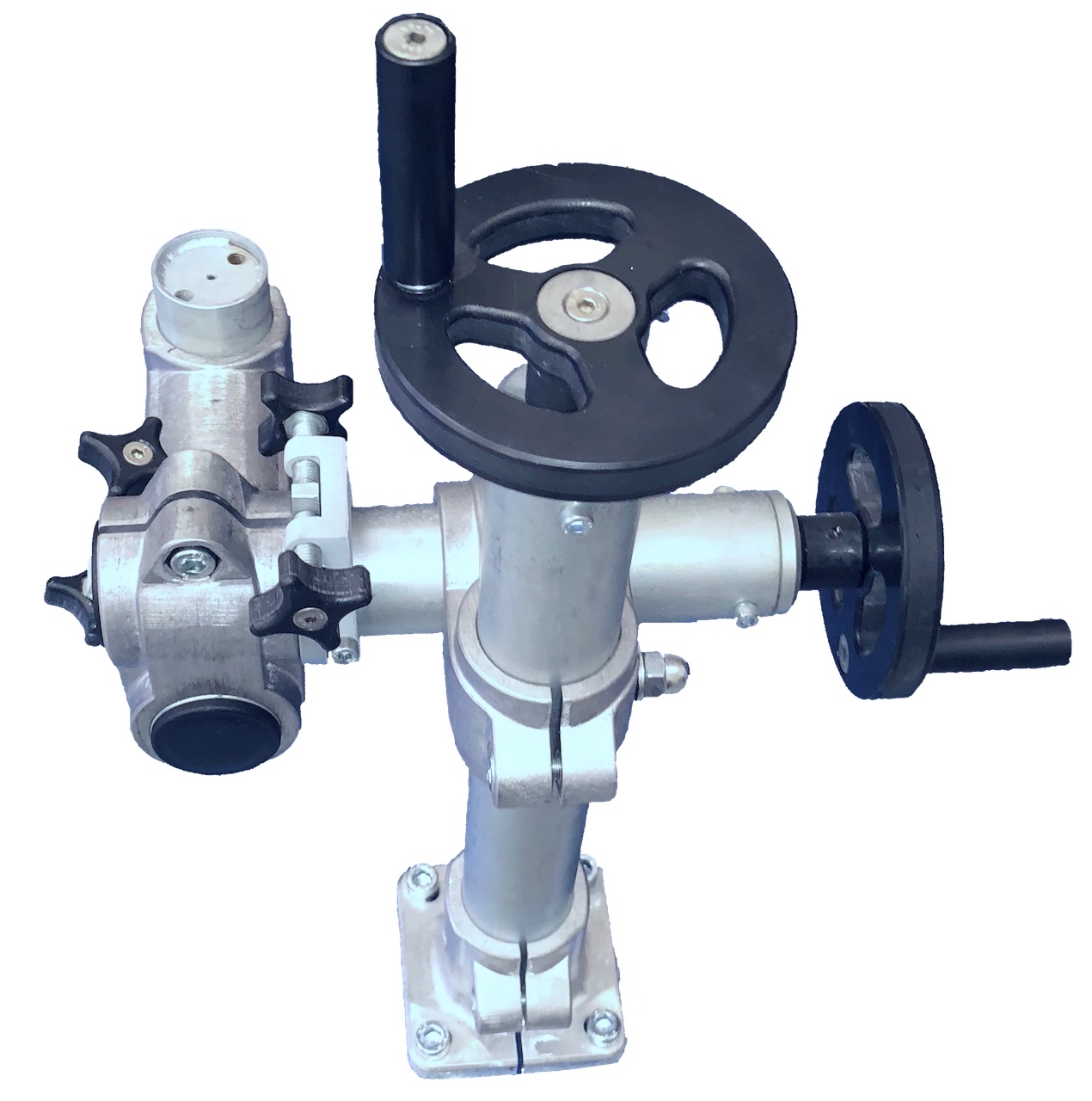

Applicator Stand

Adjusting the position of the applicator and fixing it. Five degrees of mobility.

Tables

Made according to the shape of the container, have an individual stepper drive. Responsible for the arrangement of several labels on a container relative to each other.

Stainless steel frame

Provides rigidity of the entire structure and the possibility of easy installation of modules necessary for solving the problem.

Full-wrap carousel labeling

As soon as the container comes into contact with the label and smoothing brush, the table starts to rotate it at the set speed and angle. At the moment of rotation, the brush smoothes the label, and the bottle is oriented with the reverse side to the next applicator, for applying a counter-label.

Features

Designed for manufacturers with a large range of products and high requirements for the quality of label application.

The use of independent synchronous motors with a single microprocessor control for stage rotation has a number of certain advantages:

- No axial backlash during long-term operation of the equipment.

- Possibility to set the rotation in the requested direction (both clockwise and anti-clockwise).

- Flexible adjustment of turns, both their quantity and start/end points of turns.

- Easy changeover from one type of packaging to another - just load the required template.

- Possibility to set the machine for the new task of labeling (for the containers with tooling) by own efforts without resorting to the services of the manufacturer for design changes.

Productivity

When applying the label on both sides, it is oriented and pasted over with a continuous flow, without a gap.

- 12000÷13000 bottles, vials and small (1 l) jerricans per hour.

- 6000 medium (5 l) jerricans per hour.

- 4000÷4500 large (10 l) jerricans per hour.

Accuracy of lateral application

To demonstrate the accuracy of the machine after the end of the PW, the container is passed twice. The labels will fall one on one with a deviation of 0.1-0.3 mm.

Why do we need such precision?

Container is not perfect. The variation of the container parameters will add errors, despite all the precision accuracy of the machine. But the minimum error of the labeling machine itself will help to keep within 1 mm of the total error, even with containers of poor quality.

Label invisibility effect

The design of the machine ensures the pressing and smoothing of the label until the adhesive composition adheres to the surface. The super-transparent label will be invisible, without bubbles and the moire effect. Soft, but at the same time elastic rollers allow to apply an embossed label. There will be no bubbles even inside the convex letters.

Accuracy of convergence of the circular label

Thanks to the design of the roller running-in system, the container is aligned on the side surface during the labeling process. The error of convergence of the ends of the label is minimal and for high-quality containers will be < 0.3 mm.

Ease of setup

The five-movable applicator stand has screw adjustments and allows to quickly set the desired position of the applicator relative to the container. After installation, the position of the applicator is fixed.

Synchronous drive

The speed of the conveyor and any machine module does not depend on the load, mains voltage or other external factors: adjustment during operation is not necessary. You can set up the machine and leave it for 10 years: the set speeds and delays of the machine will not change.

Onitex VA100 Control System

The control system and its interface are primarily responsible for ease of operation and readjustment.

Touch screen

The control panel is ready for operation in half a second after the machine is powered on. Any setting is available in two or three finger touches, the responsiveness of the interface is at the iPhone level. The hint system will help in case of an incorrect combination of parameters and will inform you about an emergency situation on the line. The technology used ensures that the firmware of the machine will never fall down.

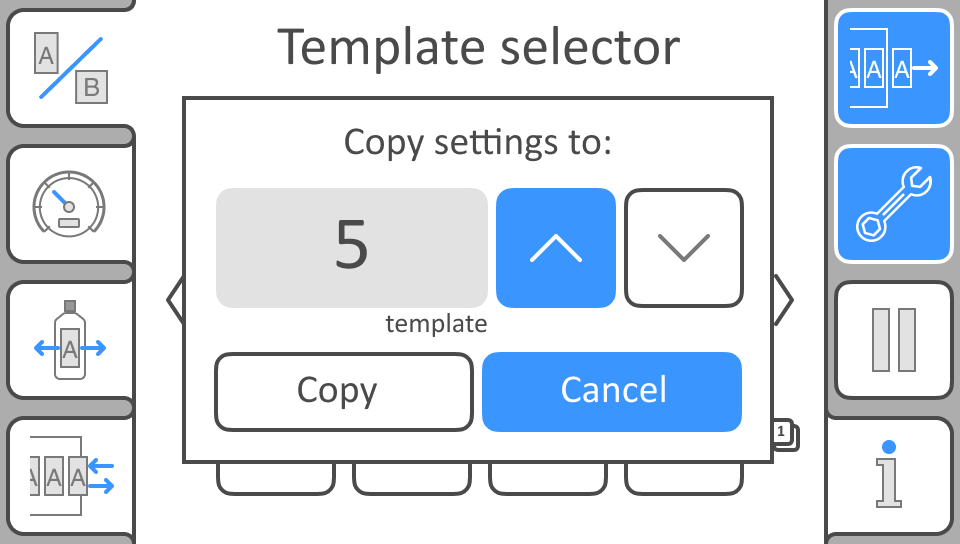

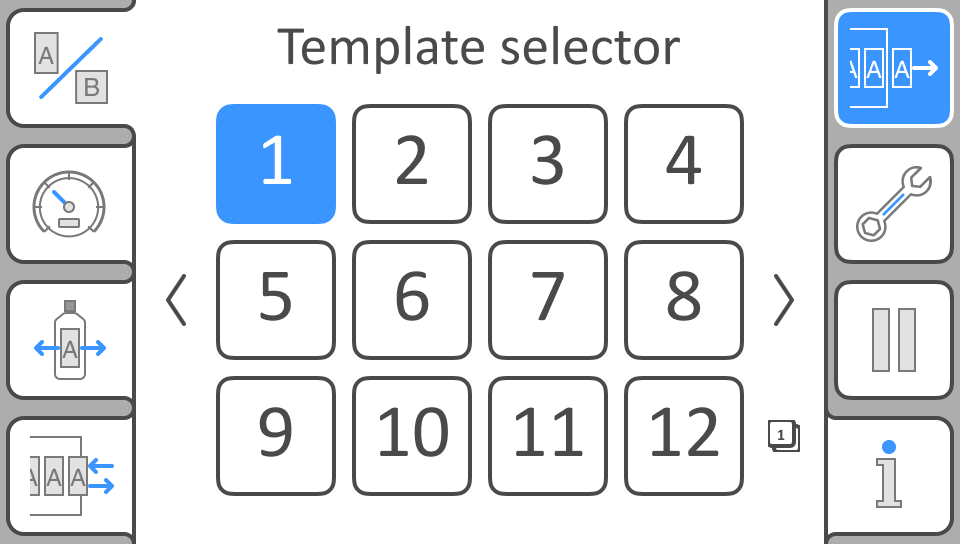

Template system

The template system radically reduces the changeover time from one type of product to another. There are 96 templates available for the operator with switching in one touch.

- Ability to both activate some modules and disable them in templates. For example, turn off the printer and the running-in unit and turn on the container orientator in the template for an oval jerrican.

- The ability to adjust the delays and speed of operation of any module or the entire line as a whole for different types of products.

- The ability to create a template of settings for one type of product, then copy the settings to another template and adjust them if necessary, so as not to configure from scratch.

During the changeover, the operator has to adjust the mechanical settings of the modules to the geometric parameters of the container and set the position of the sensors in height.

Request For Equipment

We'll help you find the right products and pricing for your business. Fill the form below or give us a call +386 69 844 278. You can also send your request to [email protected].

.jpeg?h=ae11d7a027b4d7449f0ea2e477246dae)

.jpeg?h=9f4b8b382476e38f21f855136abdb563)

.jpeg?h=d47cbd6c953d953c6cac65dabc38d26d)

.jpeg?h=41542b7bd14e422ce4ecfa5dbc51f63a)

.jpeg?h=3a662fbcd35e1e4c6b0e9cf5885b5aff)

.jpeg?h=cb55b73a0886f1e3c35c755315ce797f)

.jpeg?h=d1ebefca8a5605e8f43109737ec8369d)

.jpeg?h=b8f05a0eb53a5a3446a9ac54664e6eef)

.jpeg?h=846599732b3e3f64d0bbbc0881e7b4b9)

.jpeg?h=16c2a99a431f9eb48b82f283dea627a6)

.jpeg?h=16c2a99a431f9eb48b82f283dea627a6)

.jpeg?h=b61f57bed41b1c8b666d130364f5cd26)