Appearance

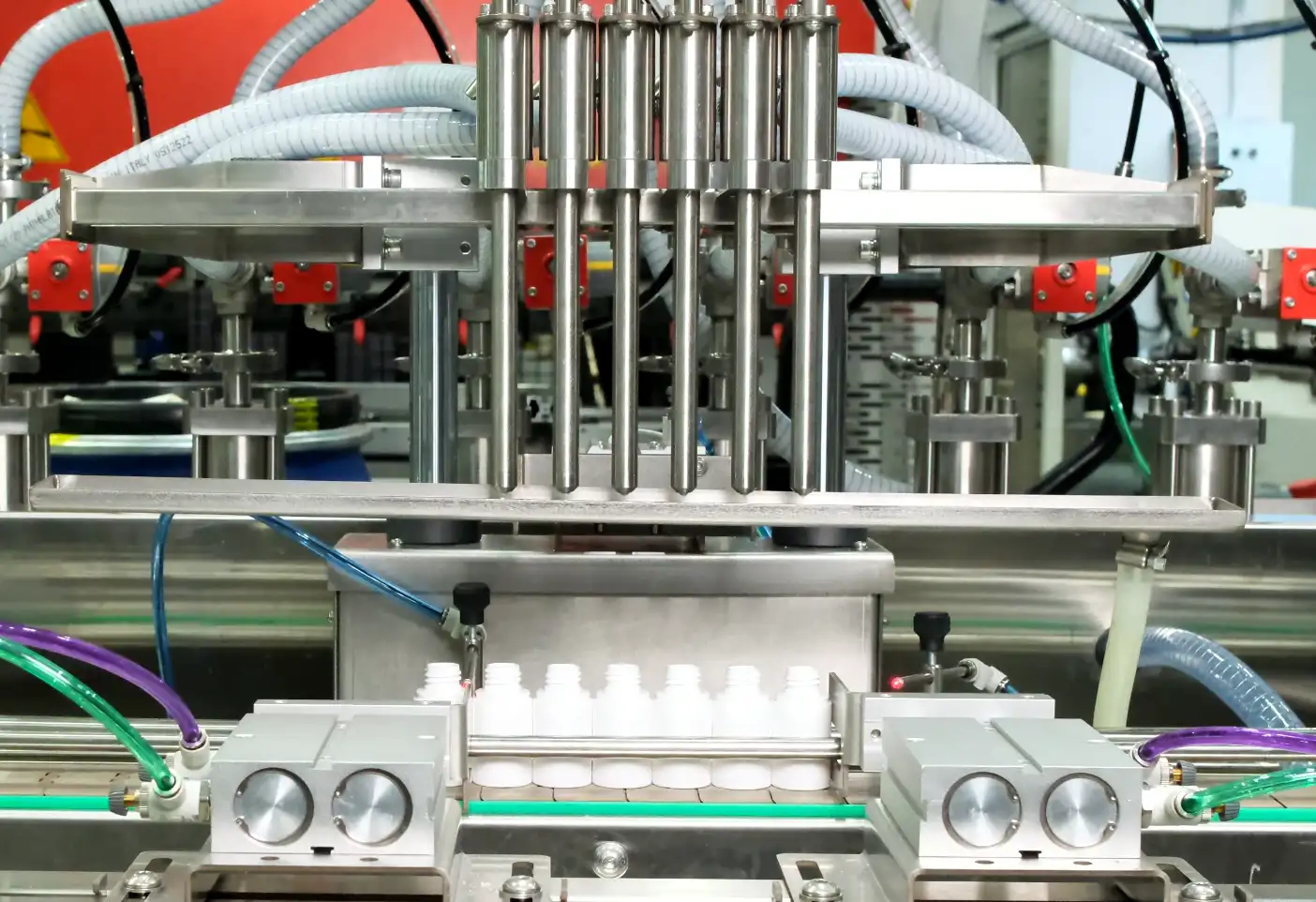

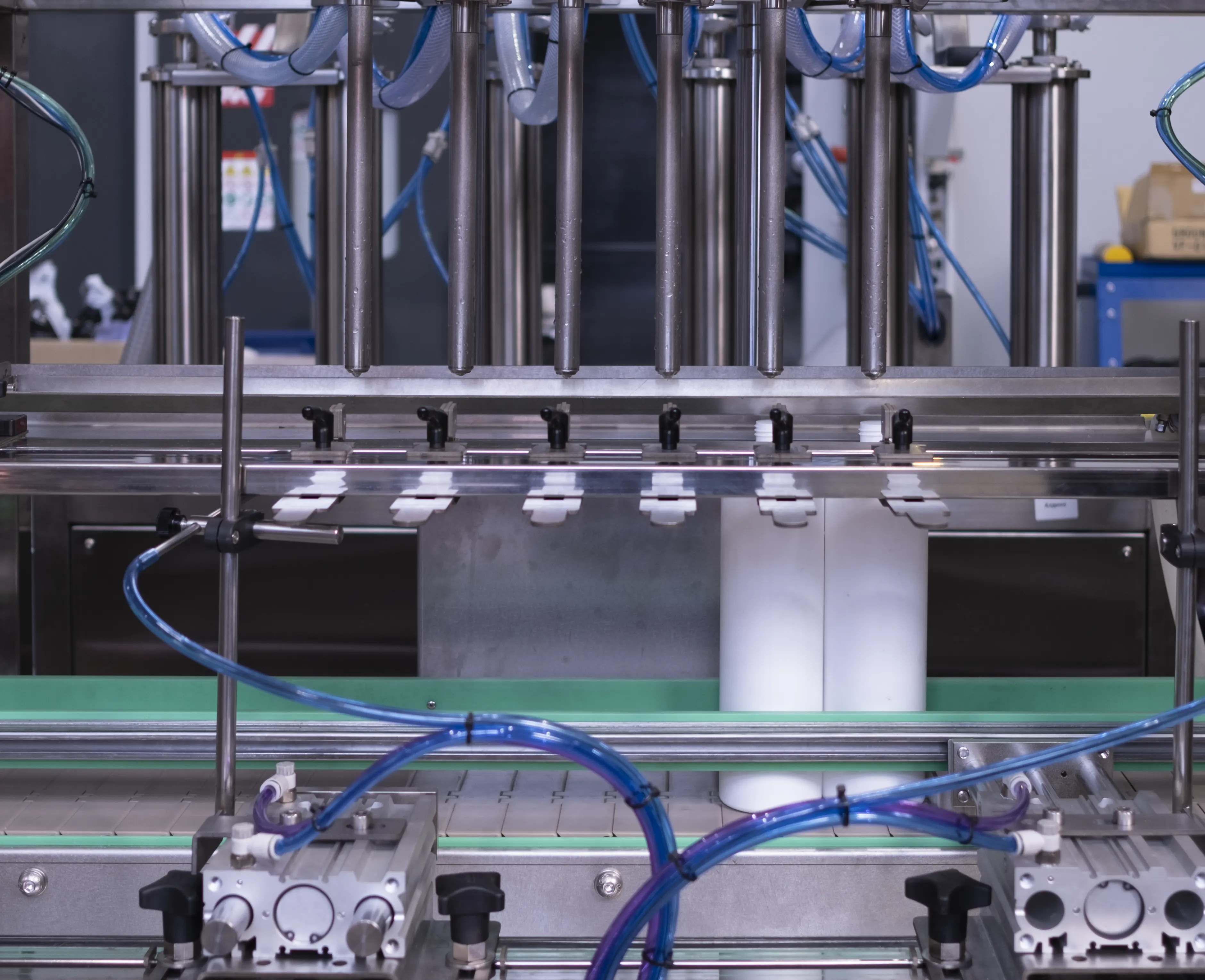

The design of the machine allows the installation of various modules depending on the task:

Gate Valve Filler

Electromagnetic Flowmeter

Pulsation Dampener

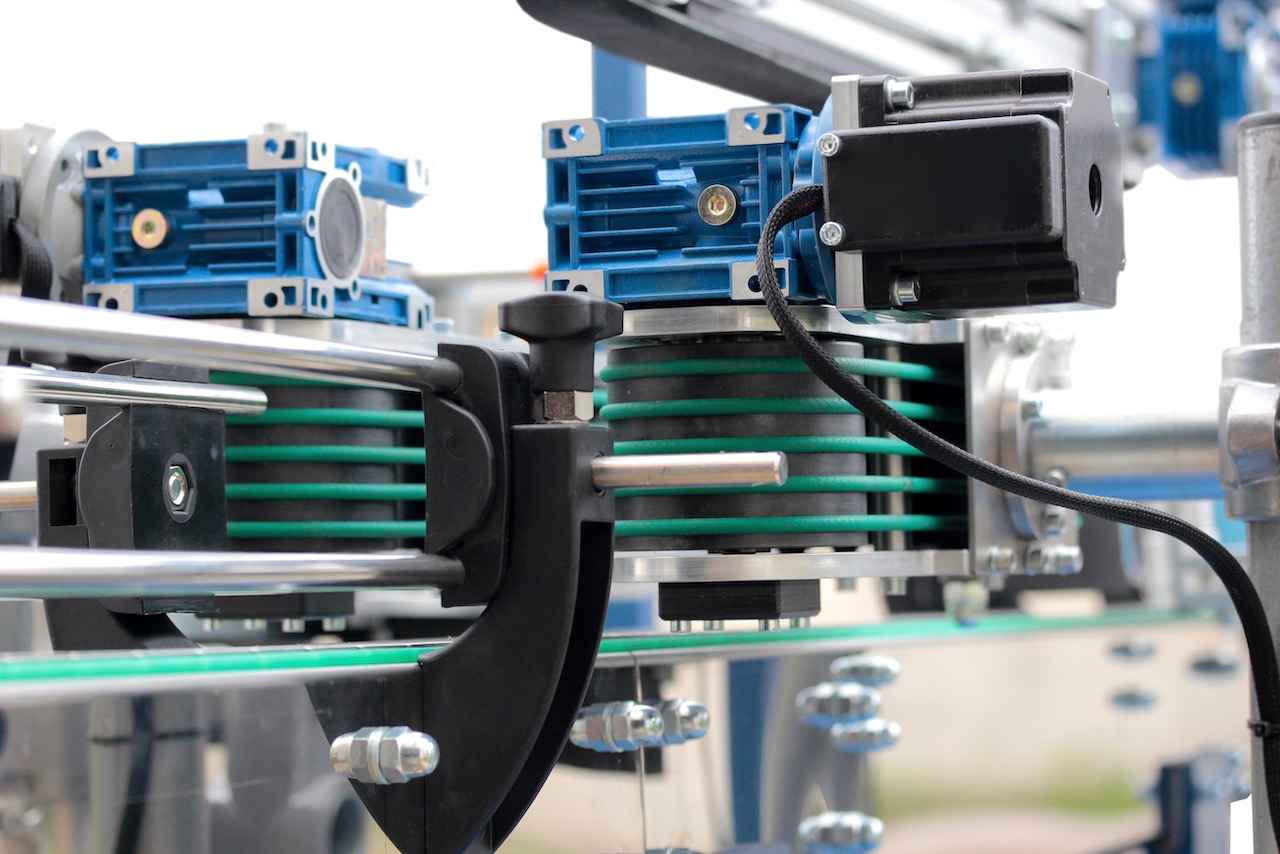

Conveyor

Chain conveyor for the supply and removal of containers.

Touch screen

The control panel is ready for operation in half a second after the machine is powered on. Any setting is available in two or three finger touches, the responsiveness of the interface is at the iPhone level. The hint system will help in case of an incorrect combination of parameters and will inform you about an emergency situation on the line. The technology used ensures that the firmware of the machine will never fall down.

Fillers

Cutter

Stainless steel frame

Provides rigidity of the entire structure.

Features

Designed for manufacturers with a wide range of products and high demands for speed and accuracy of dosing.

We currently provide automatic filling lines to companies operating in the following industries:

- Food industry

- Cosmetic industry

- Pharmaceutical industry

- Chemical industry

Productivity

Absence of moving parts or constrictions in the measuring path of the filler allows to achieve high productivity:

- 2500÷3000 bottles, vials and canisters (1L) per hour.

- 3000÷3500 bottles, vials (0.5 l) per hour.

- 3500÷4000 bottles (0.25 l) per hour.

Why does filling precision matter?

With our electromagnetic dispenser, filling accuracy is less than 0.5% and is not affected by changes in fluid viscosity, density or temperature.

Synchronous drive

The speed of the conveyor and any machine module does not depend on the load, mains voltage or other external factors: adjustment during operation is not necessary. You can set up the machine and leave it for 10 years: the set speeds and delays of the machine will not change.

Ease of setup

The five-movable applicator stand has screw adjustments and allows to quickly set the desired position of the applicator relative to the container. After installation, the position of the applicator is fixed.

Onitex VA100 Control System

The control system and its interface are primarily responsible for ease of operation and readjustment.

Touch screen

The control panel is ready for operation in half a second after the machine is powered on. Any setting is available in two or three finger touches, the responsiveness of the interface is at the iPhone level. The hint system will help in case of an incorrect combination of parameters and will inform you about an emergency situation on the line. The technology used ensures that the firmware of the machine will never fall down.

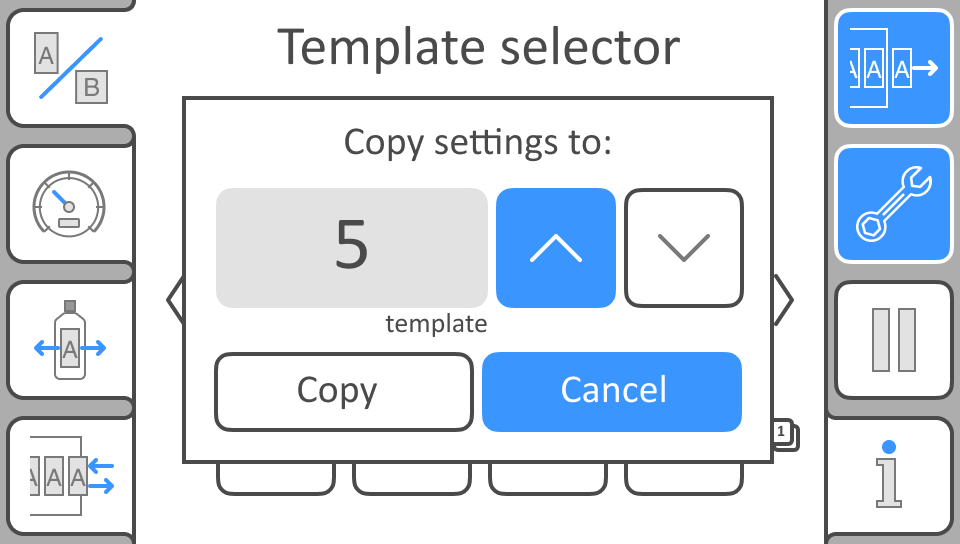

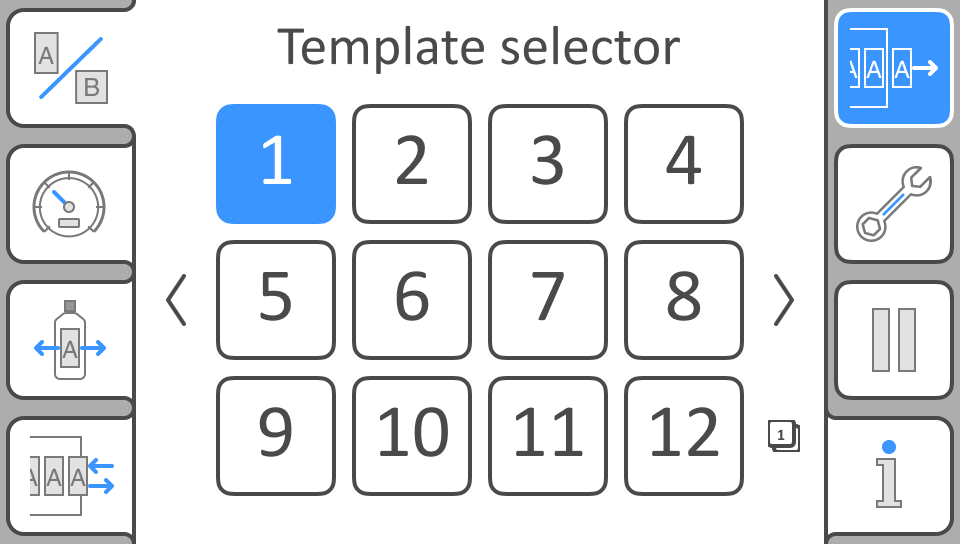

Template system

The template system radically reduces the changeover time from one type of product to another. There are 96 templates available for the operator with switching in one touch.

- Ability to both activate some modules and disable them in templates. For example, turn off the printer and the running-in unit and turn on the container orientator in the template for an oval jerrican.

- The ability to adjust the delays and speed of operation of any module or the entire line as a whole for different types of products.

- The ability to create a template of settings for one type of product, then copy the settings to another template and adjust them if necessary, so as not to configure from scratch.

During the changeover, the operator has to adjust the mechanical settings of the modules to the geometric parameters of the container and set the position of the sensors in height.

Request For Equipment

We'll help you find the right products and pricing for your business. Fill the form below or give us a call +386 69 844 278. You can also send your request to [email protected].