Appearance

The design of the machine allows the installation of various modules depending on the task:

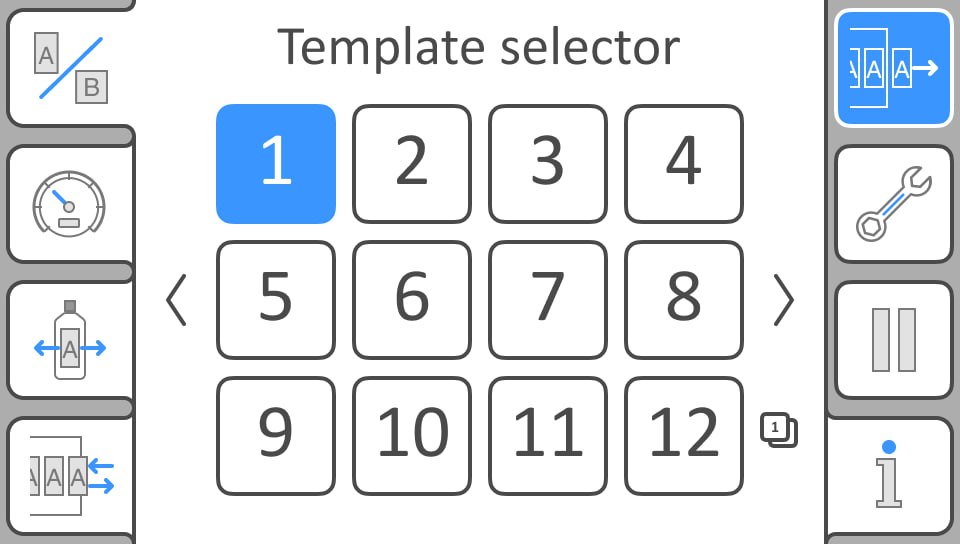

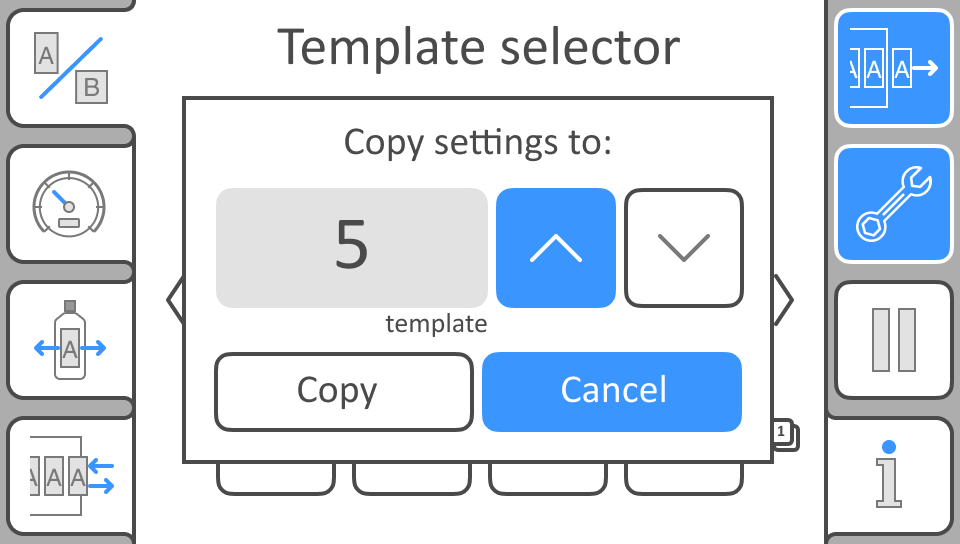

Touch screen

All modules of the machine are controlled and configured from the screen, settings templates are switched for different containers. Two synchronized panels for operator convenience.

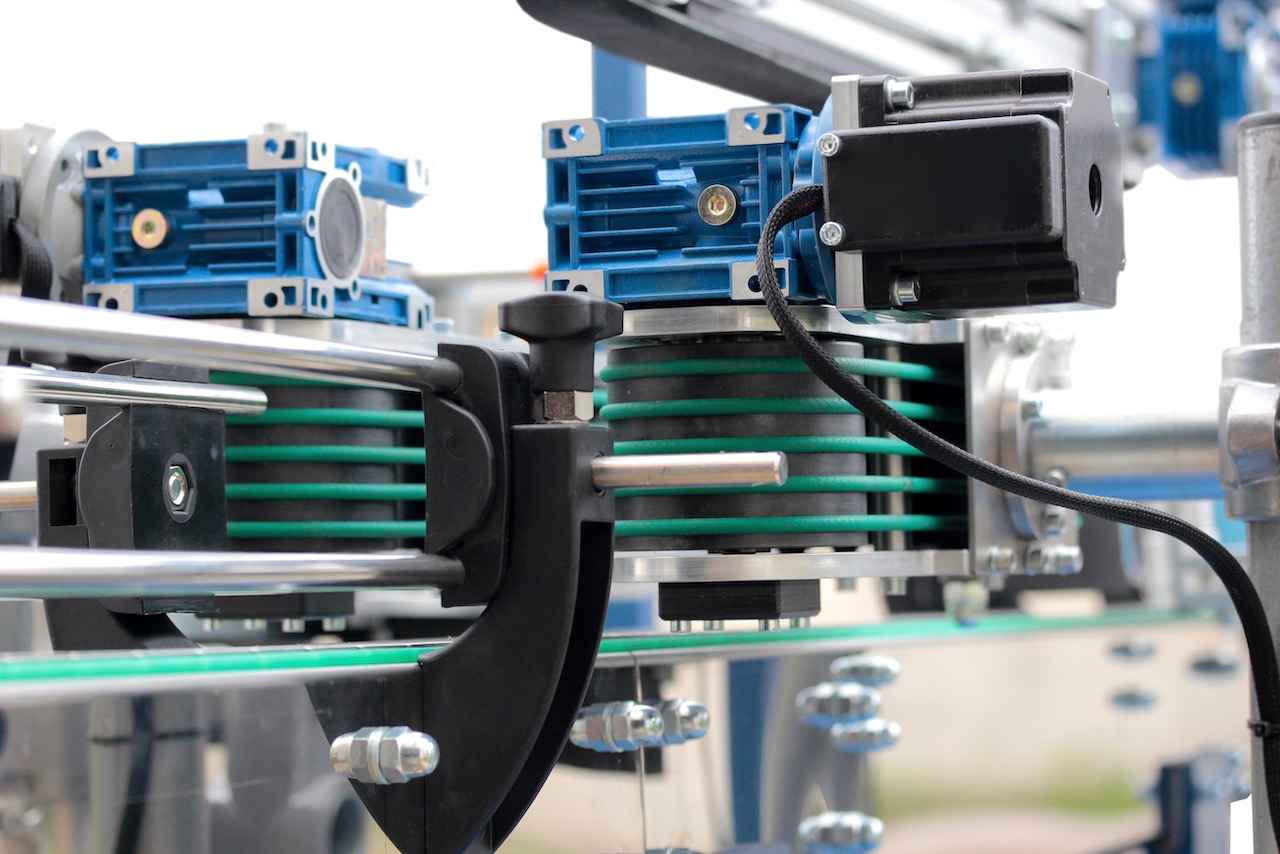

Intermittent drive of the conveyor

Provides precision stability in speed: the speed of the conveyor does not depend on the load.

Roller running-in unit

Fixes and rotates cylindrical or conical containers for applying a circular label. Aligns the container for precise convergence of the ends of the label. Synchronized with the applicator using an intermittent drive.

Applicator A150

Issues the label at the right moment, with the right speed and tension of the tape. The label height is up to 300mm, depending on the applicator model.

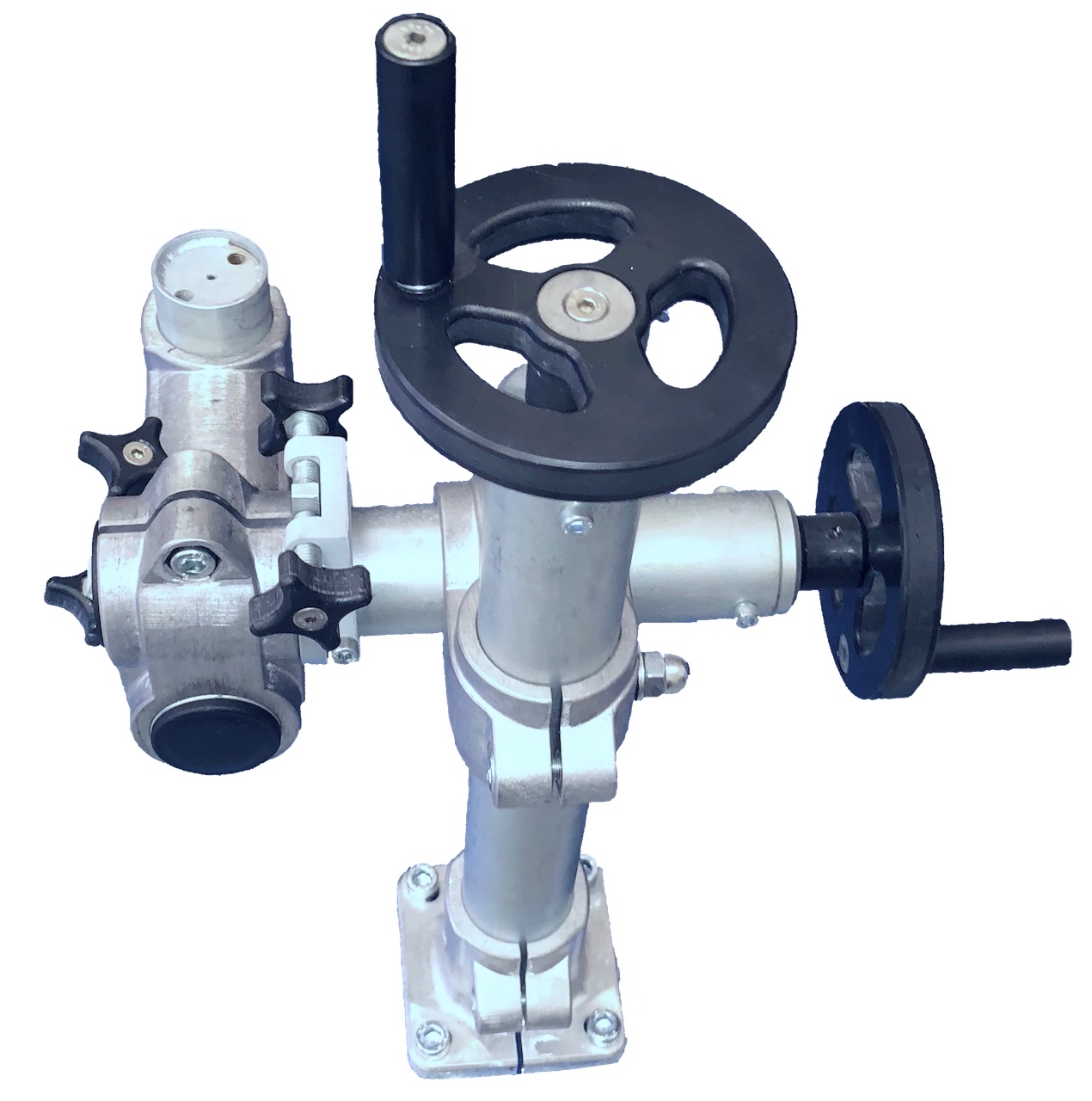

Applicator Stand

Adjusting the position of the applicator and fixing it. Five degrees of mobility.

Stainless steel frame

Provides rigidity of the entire structure and the possibility of easy installation of modules necessary for solving the problem.

.jpeg?h=ae11d7a027b4d7449f0ea2e477246dae)

.jpeg?h=9f4b8b382476e38f21f855136abdb563)

.jpeg?h=d47cbd6c953d953c6cac65dabc38d26d)

.jpeg?h=41542b7bd14e422ce4ecfa5dbc51f63a)

.jpeg?h=3a662fbcd35e1e4c6b0e9cf5885b5aff)

.jpeg?h=cb55b73a0886f1e3c35c755315ce797f)

.jpeg?h=d1ebefca8a5605e8f43109737ec8369d)

.jpeg?h=b8f05a0eb53a5a3446a9ac54664e6eef)

.jpeg?h=846599732b3e3f64d0bbbc0881e7b4b9)

.jpeg?h=16c2a99a431f9eb48b82f283dea627a6)

.jpeg?h=16c2a99a431f9eb48b82f283dea627a6)

.jpeg?h=b61f57bed41b1c8b666d130364f5cd26)